China 6 Axis 1800mm Arm fihla ka ho iketsa Steel MIG Welding Robotic Arm

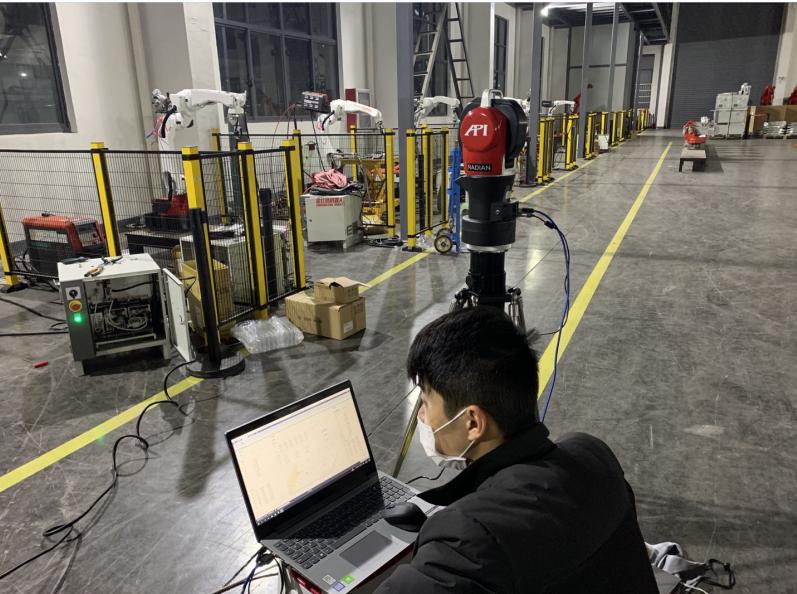

LASER CALIBRATION TEKO REPOSITIONING NEPAHETSO

JHY e sebelisa mokhoa oa laser calibration ho leka ho nepahala ha boemo bo pheta-phetoang ba roboto.Ka mor'a liteko tse ngata, ho nepahala ha boemo bo pheta-phetoang ba roboto ea rona ho phahame haholo ho feta ± 0.08mm.

SEBELISA LITLHAKISO TSE KHOLO BAKENG SA LIHLOOHO TSA KORE

Lisebelisoa tsa mantlha tsa roboto tse kang servo motor, RV reducer, harmonic reducer, servo drive joalo-joalo kaofela li sebelisa lihlahisoa tse holimo tsa Chaena, tse lekiloeng ke tšebeliso ea rona ea nako e telele ho netefatsa hore li loketse roboto ea rona.

TS'ELISO BONOLO

Tlhokomelo e bonolo, Ho ea ka tataiso ea tlhokomelo e fanoeng ke rona bareki ka bobona ba ka sebetsa habonolo.

MOR'A THEKISO TIISETSO

Moreki e mong le e mong o na le sehlopha sa hae sa litšebeletso tsa kamora thekiso.Haeba o hloka thuso efe kapa efe ka mor'a thekiso, Pls botsa neng kapa neng.Baenjiniere ba rona ba litsebi ba tla e rarolla ka nako e khuts'oane.Taba ke hore tsohle ke mahala.

| Litaelo tsa welding bakeng sa tšepe e bonolo le tšepe e tlase ea alloy | |||||||||

| mofuta | poleiti | Wire bophara | lekhalo la metso | tjheseletsa jwale | welding voltage | lebelo la ho tjheseletsa | Ikopanye le malebela a malebela | Phallo ea khase | Welding angle |

| Ho cheselletsa butle ka sebopeho sa T | 1.0 | 0.8 | 2.5-3 | 70-80 | 17-18 | 8-10 | 10 | 10-15 | 45° |

| 1.2 | 1.0 | 3 ho isa ho 3.5 | 85-90 | 18-19 | 8-10 | 10 | 10-15 | 45° | |

| 1.6 | 1.0,1.2 | 3 ho isa ho 3.5 | 100 ~ 110 | 18-19.5 | 8-10 | 10 | 10-15 | 45° | |

| 2.0 | 1.0,1.2 | 3 ho isa ho 3.5 | 115-125 | 19.5-20 | 8-10 | 10 | 10-15 | 45° | |

| 2.3 | 1.0,1.2 | 3 ho isa ho 3.5 | 130-140 | 19.5-21 | 8-10 | 10 | 10-15 | 45° | |

| 3.2 | 1.0,1.2 | 3.5-4 | 150-170 | 21-22 | 7.5-8 | 15 | 15-20 | 45° | |

| 4.5 | 1.0,1.2 | 4.5-5 | 180-220 | 21-23 | 6.5 ho isa ho 7.5 | 15 | 15-20 | 45° | |

| 1.2 | 5 - 5.5 | 200 ~ 250 | 24-26 | 6.5-8 | 10-15 | 10 - 20 | 45° | ||

| 6 | 1.2 | 5 - 5.5 | 230-260 | 25-27 | 6.5 ho isa ho 7.5 | 20 | 15-20 | 45° | |

| 6 | 220-250 | 25-27 | 5.5 ho isa ho 7.5 | 13-18 | 10 - 20 | 45° | |||

| 4 ho isa ho 4.5 | 270-300 | 28-31 | 10 ho isa ho 11.5 | 13-18 | 10 - 20 | 45° | |||

| 8,9 | 1.2,1.6 | 6 - 7 | 270-380 | 29-35 | 6.5 ho isa ho 7.5 | 25 | 20-25 | 50° | |

| 8 | 1.2 | 5 - 6 | 270-300 | 28-31 | 9-10 | 13-18 | 10 - 20 | 45° | |

| 1.2 | 7-8 | 260-300 | 26-32 | 4 - 5.5 | 15-20 | 10 - 20 | 50° | ||

| 1.6 | 6.5-7 | 300-330 | 30-34 | 5 - 5.5 | 15-20 | 10 - 20 | 50° | ||

| 12 | 1.2,1.6 | 7-8 | 270-380 | 27-35 | 4.5 ho isa ho 6.5 | 20-25 | 20-25 | 50° | |

| 1.2 | 7-8 | 260-300 | 26-32 | 4 - 5.5 | 15-20 | 10 - 20 | 50° | ||

| 1.6 | 6.5-7 | 300-330 | 30-34 | 5 - 6 | 15-20 | 10 - 20 | 50° | ||

Hlokomela:

1. MIG welding e sebelisa khase ea inert, haholo-holo e sebelisetsoang ho cheselletsa aluminium le li-alloys tsa eona, koporo le li-alloys tsa eona, titanium le lisebelisoa tsa eona, hammoho le tšepe e sa hloekang le tšepe e sa keneleng mocheso.tjheseletsa ea MAG le CO2 e sirelelitsoeng ka khase e sebelisoa haholo bakeng sa tšepe ea khabone le tšepe e tlase e matla haholo.

2. Likahare tse ka holimo ke tsa litšupiso feela, 'me ho molemo ho fumana mekhoa e nepahetseng ea ts'ebetso ea welding ka ho netefatsa liteko.Li-diameter tse ka holimo tsa terata li thehiloe ho mehlala ea sebele.