China 6 axis 1500m robot arm metal frame mig welding robot

Patents le Liqapi

Phetiso ea bobeli ea 6-axis E fetotsoe ho likhokahanyo tse peli tsa mabanta, e ekelitse karo-karolelano ea phetisetso, 'me ea rarolla bothata ba 6- axis e tsamaeang ka potlako le e sa nepahalang.Disc e hlahisoang ke li-axis ea botšelela e entsoe ntle le likere, e nang le mochine o fetisang ka mokhoa o nepahetseng haholo, o ntlafatsang ho nepahala ha motsamao oa axis ea botšelela ... Hajoale re na le litokelo tse fetang 30 tse amanang le roboto ea welding.

Sebopeho sa Software Bakeng sa Mochini oa Welding oa Artsen Pro

| Mohlala | Sephutheloana sa software | Lintho tse chesehang | Mofuta oa theknoloji | Synergy | Synergy e khethehileng |

| Artsen Pro500P(R) | PP | Tšepe e tiileng ea carbon, e tiileng e se nang letheba | Phetisetso e khuts'oane ea potoloho, sekhahla se khuts'oane sa arc | ho joalo | no |

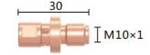

Welding Torch Technicalspecification

Mokhoa oa ho futhumatsa: Pholiso ea metsi

Lintlha: 550A CO2,500A MIXED GAS M21(ISO14175)

Nako ea mosebetsi: 100%

terata bophara: 0.8 ~ 1.6MM

Torch geometries: 22°,36°,45°,180°

*Molala o fetohang oa khantsi o nang le ts'ebetso ea ho emisa metsi.Ho bonolo ho fetola molala oa likhantsi le ho etsa tlhokomelo.

* Ts'ebetso ea brake ea mohala (boikhethelo)

* Ka sensor ea ho ts'oha (ho ikhethela)

* Likhetho tse ngata bakeng sa li-angle tse fapaneng tsa molala le bolelele.

* E-ba teng bakeng sa khokahano e tsebahalang ea terata joalo ka.Lincoln Panasonic European style joalo-joalo.

| Litaelo tsa welding bakeng sa tšepe e bonolo le tšepe e tlase ea alloy | |||||||||

| mofuta | poleiti | Wire bophara | lekhalo la metso | tjheseletsa jwale | welding voltage | lebelo la ho tjheseletsa | bohale bo bohlasoa | Phallo ea khase | |

| Sebopego sa V | 12 | 1.2 | 0 ~ 0.5 | kantle1 | 300 ~ 350 | 32-35 | 5 ho isa ho 6.5 | 4 - 6 | 20-25 |

| ka hare 1 | 300 ~ 350 | 32-35 | 7.5 ho isa ho 8.5 | 20-25 | |||||

| 1.6 | kantle1 | 380-420 | 36-39 | 5.5 ho isa ho 6.5 | 20-25 | ||||

| ka hare 1 | 380-420 | 36-39 | 7.5 ho isa ho 8.5 | 20-25 | |||||

| 16 | 1.2 | 0 ~ 0.5 | kantle1 | 300 ~ 350 | 32-35 | 4 - 5 | 4 - 6 | 20-25 | |

| ka hare 1 | 300 ~ 350 | 32-35 | 5 - 6 | 20-25 | |||||

| 1.6 | kantle1 | 380-420 | 36-39 | 5 - 6 | 20-25 | ||||

| ka hare 1 | 380-420 | 36-39 | 6 ho isa ho 6.5 | 20-25 | |||||

| Hlokomela: 1. MIG welding e sebelisa khase ea inert, haholo-holo e sebelisetsoang ho cheselletsa aluminium le li-alloys tsa eona, koporo le li-alloys tsa eona, titanium le lisebelisoa tsa eona, hammoho le tšepe e sa hloekang le tšepe e sa keneleng mocheso.tjheseletsa ea MAG le CO2 e sirelelitsoeng ka khase e sebelisoa haholo bakeng sa tšepe ea khabone le tšepe e tlase e matla haholo. 2. Likahare tse ka holimo ke tsa litšupiso feela, 'me ho molemo ho fumana mekhoa e nepahetseng ea ts'ebetso ea welding ka ho netefatsa liteko.Li-diameter tse ka holimo tsa terata li thehiloe ho mehlala ea sebele. | |||||||||